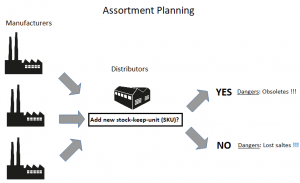

One of the main challenges to grow your business and meet the needs of your customers is to introduce new stock-keep-units (SKU) in your warehouse.

It’s easy to turn cash into inventory but the challenge is to turn inventory back into cash!

How do you quickly identify and react to changes in your customer purchasing needs? How do you create accurate sales forecasts for new products when there is no sales history at all?

Considering that you, as a distributor, have to introduce hundreds of new SKUs every year, we are really talking about a very delicate issue.

How does the distributor traditionally decide to introduce new products into warehouse? By intuition, because the price is attractive, by the type of application, by recommendations of the supplier, because some customer has requested it, etc.

Well, all of these decision criteria are inaccurate and potentially the source of most dead inventory. That is, it’s dead on arrival.

How can you improve decisions about parts inventory?

Demand data becomes insight into market behavior that help you to make the most accurate decisions regarding inventory. The beauty of demand data is that by tracking changes over time, you can actually evaluate the sales potential of any new-SKU before making any decision.

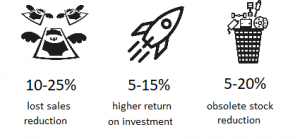

This represents a win-win-win situation for you: lost sales reduction, higher return on investment and obsolete stock reduction.

Companies that analyze and use systematically demand data, presents the following business improvements:

Summary: Demand data analysis, combined with the most up-to-date parts information available on the market, cleverly grouped, allow to systematically detect all products with demand that are not yet in the warehouse.

Market Expert: information and decision system for automotive aftermarket parts distributors.

By Joan Cabós

CEO & founder

CEO & founder