Managing parts for the Industrial, Agricultural or Marine application segments (among others) represents an added level of complexity. In a previous article, we advanced a few key points about these application segments: Article

For one thing, there’s no vehicle park definition which structures all applications in existence and for another, the information available on the market is scarcer and harder to find.

If, to all this, we add that the cost of these parts is normally much higher than the cost of the ones in light vehicles, we are faced with a great challenge for wholesalers, distributors and manufacturers.

What products should we manufacture or store for our customers? How can we improve our decisions?

Well, you’ll have to forgive me, but going into sarcastic mode for a moment, we can always use the method of trial and error, incorporating or manufacturing products and finding out along the way if they are selling well or don’t have much demand, or if we’re missing some and decide to start incorporating them as the months go by.

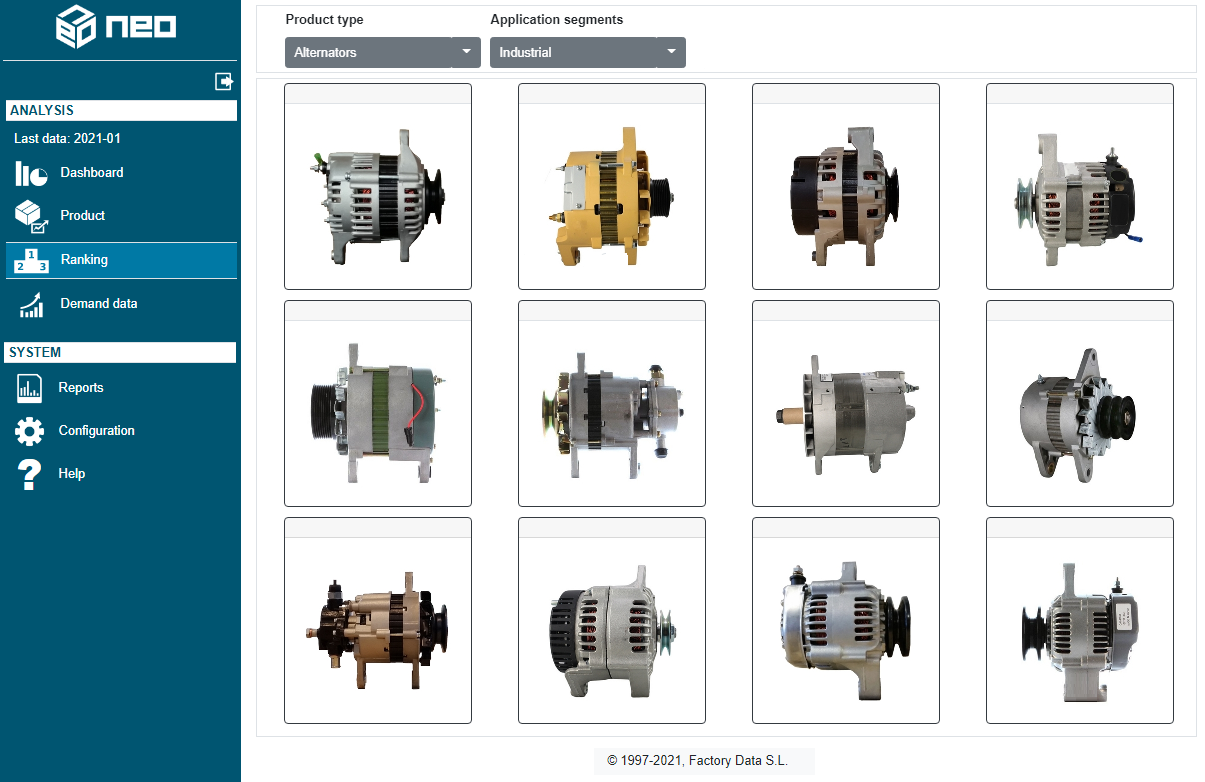

Factory Data has developed a totally disruptive system which, on the one hand, combines the definition of all existing products on the market, for any application segment we wish to analyse, and on the other, precise information on demand levels, from any geographic area, to thereby estimate the sales potentials of all existing products.

A few months ago, we explained our process in an article: Article , but now we’re going to explain how to put this technology into practice for the case at hand:

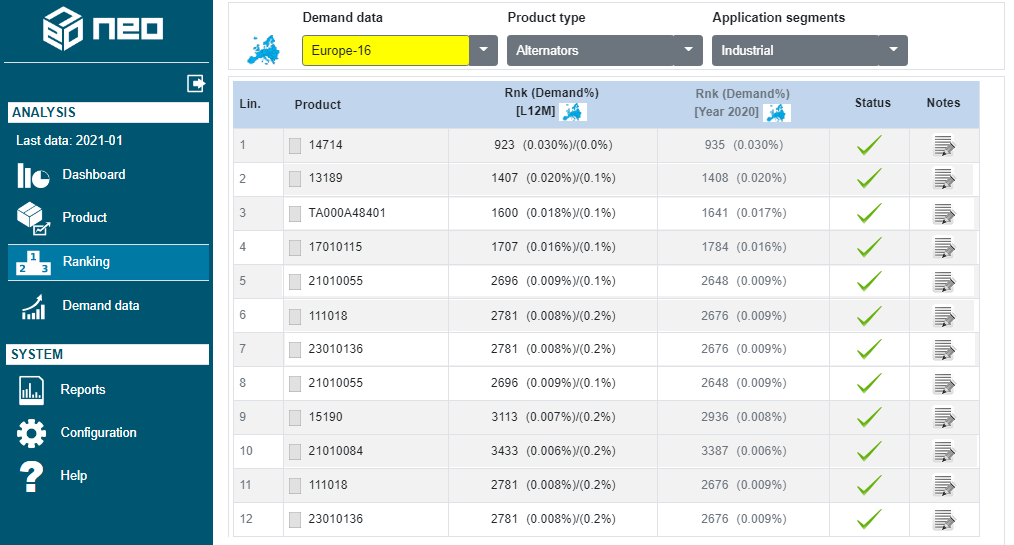

1) Select a product family and an application segment to discover all existing products on the market.

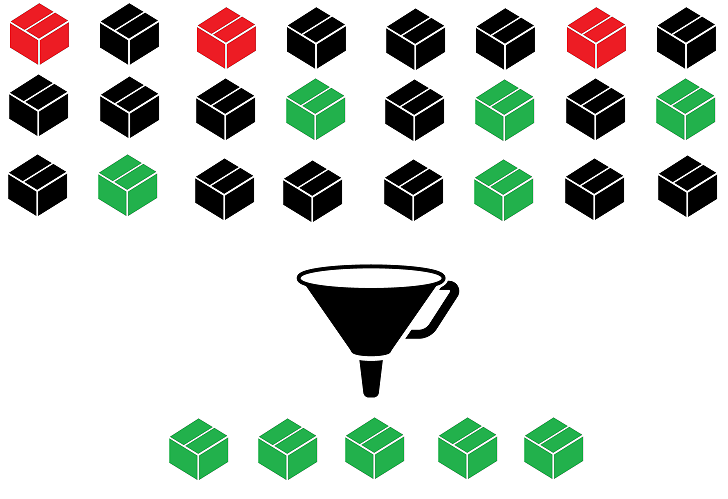

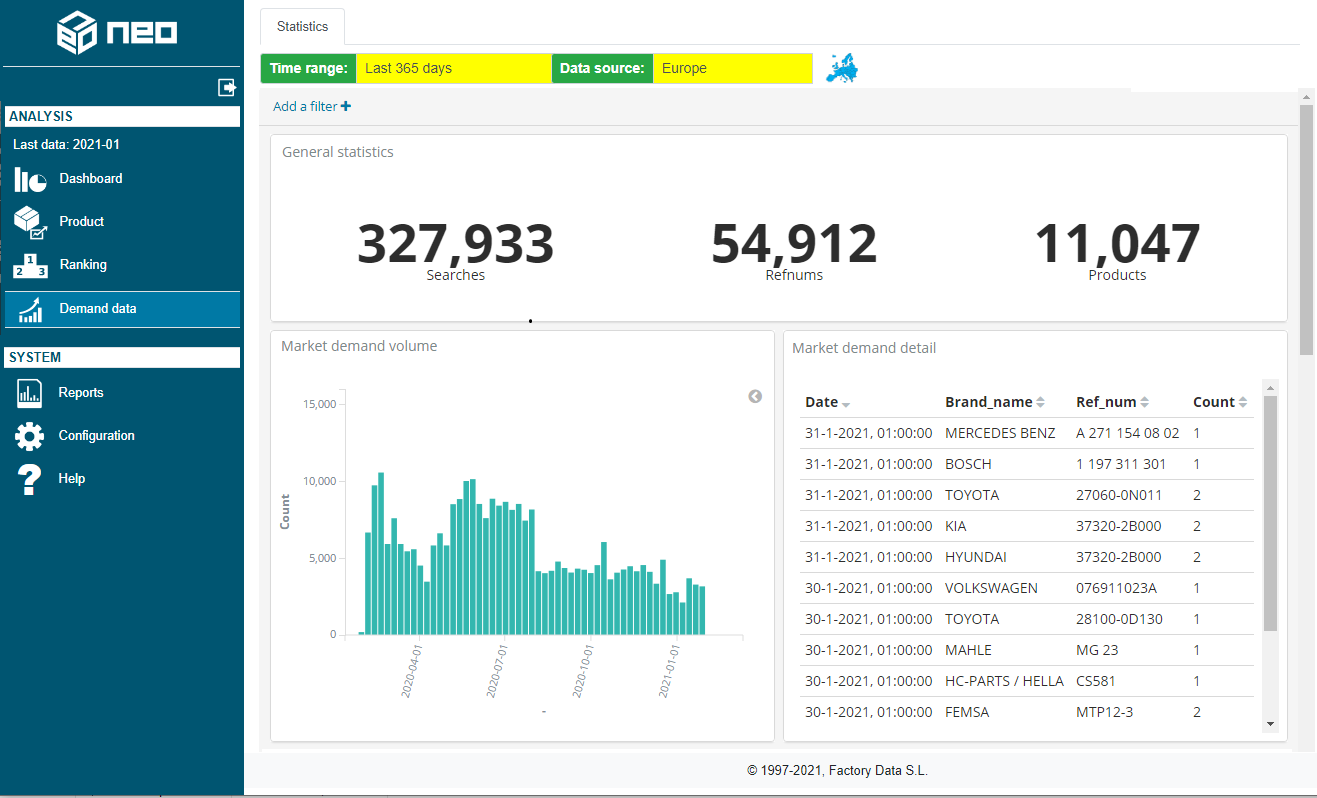

2) Select a demand signals repository that represent market demand in a specific geographic area.

3) Combine both data sets to create a ranking of products ordered by demand level.

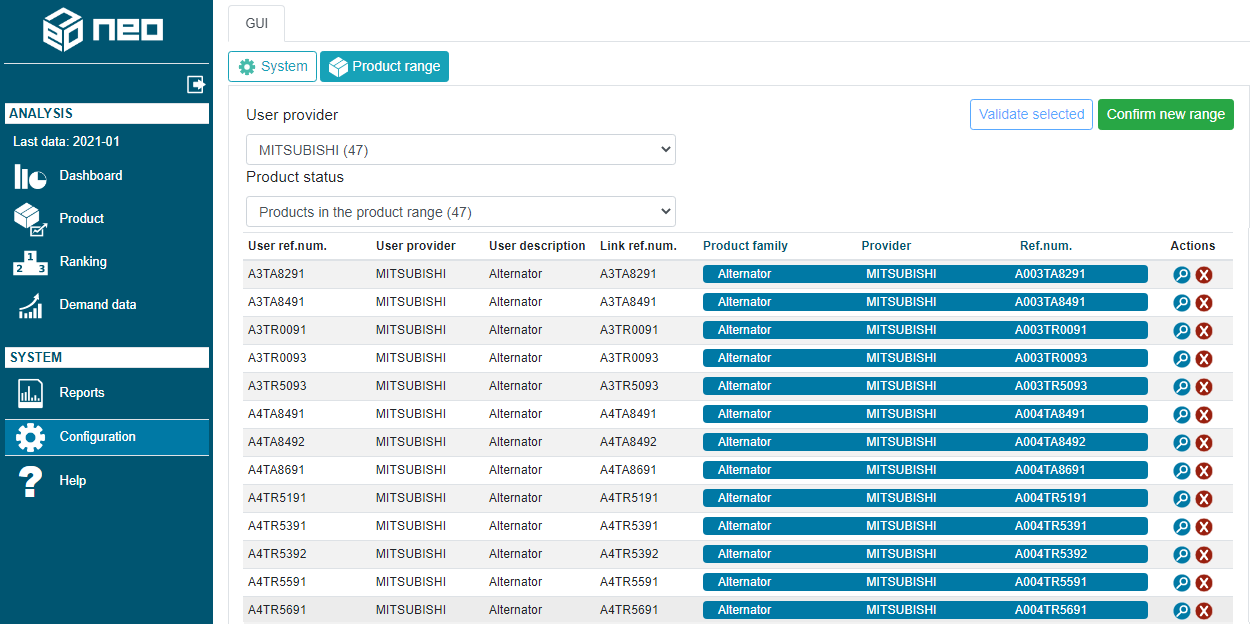

4) Provide the system with the list of reference numbers you currently manufacture or distribute.

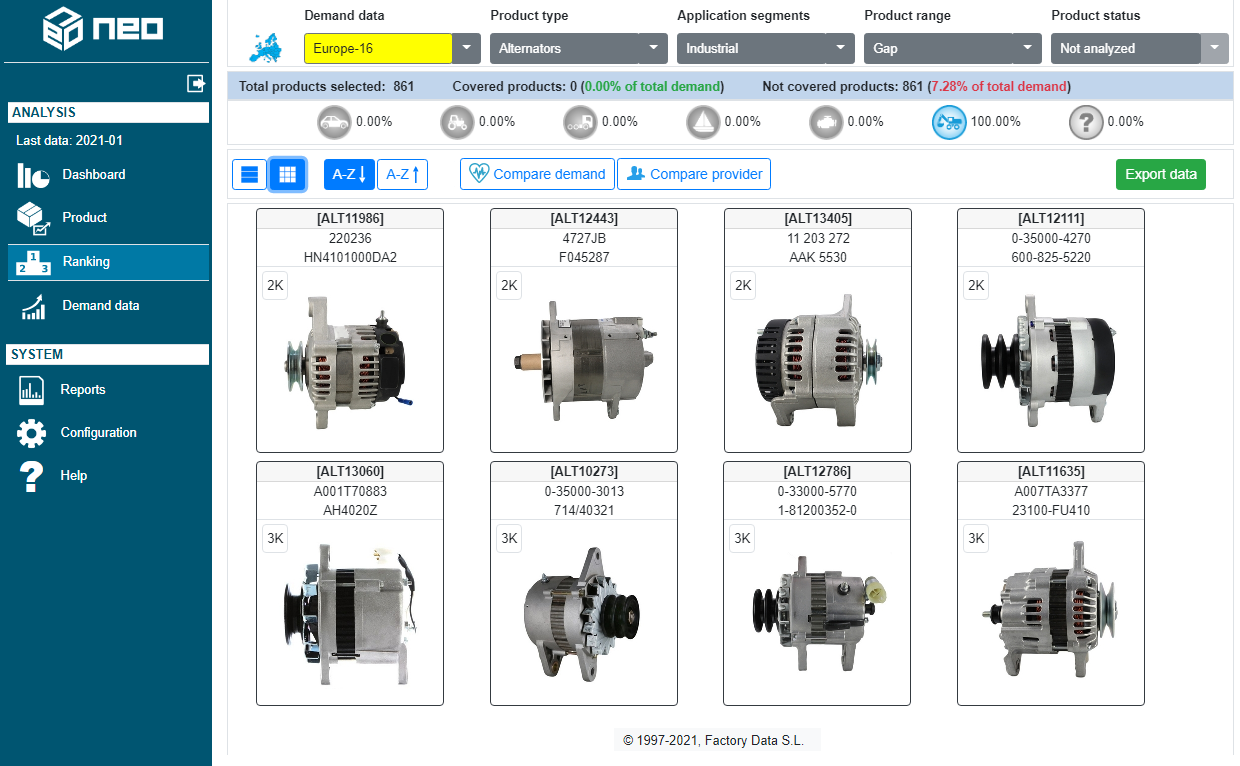

5) The system will now be able to detect all the high sales potential products you’re missing. If you want, you can select various manufacturers or distributors to see which ones currently have your missing products in their product ranges.

And now all you have to do is go down the list and analyse the products one by one, in order of their sales potential, to decide if you want to manufacture or acquire them.

In less than one hour a month, you can optimally manage your product range, incorporating products with higher sales potential and removing those which are already obsolete.

By Joan Cabós

CEO & founder