Today we’re going to talk about “interchangeability”, a term that sounds a bit extravagant but serves as the explanation for why some spare parts specialists find up to 400% more solutions than the rest.

Interchangeability consists in the possibility of offering or selling an alternative product whose reference number is different from the one of the product they’re asking us for, but which serves as a perfect substitute.

This ability to find solutions allows great specialists to offer solutions for many more products with fewer reference numbers in their product ranges. It seems fantastic, doesn’t it?

At first we might think that all the possibilities of interchangeability between products are perfectly published and known by everyone, but this is very far from reality.

Clearly, some players on the market don’t have too much interest in these possibilities being known. Because, otherwise, how would they sell new products to replace the old ones? How would they sell five difference reference numbers if we found out all five could be simplified by one alone?

The problem is that since there are no common criteria for determining if two products are the same or not, there is no way of knowing whether or not somebody’s products are repeated. It seems silly, but what’s happening is really that simple.

At Factory Data, we developed an algorithm which uses the majority criteria of the aftermarket (represented by 15-20 distributors and manufacturers) to determine whether two products are different or not. And after all these years of work, the magic arrived: we were able to determine how many distinct products exist on the entire market!!

This way, now we can compare, in terms of interchangeability, any brand or product range selection on the market with respect to the majority criteria to know what type of service we are being offered.

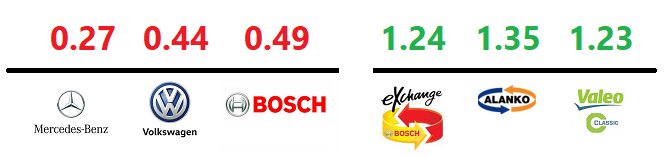

Here are the interchangeability ratios for certain brands’ selections of alternators and starter motors:

As we can see, vehicle manufacturers like MERCEDES BENZ or VOLKSWAGEN tend to have a very low interchangeability rate. For them, A is A and B is B; there are no other options. Something similar occur with OEM parts manufacturers product ranges.

For IAM manufacturers, however, the ratios are much higher, meaning that with each one of their products we could serve more than one existing product.

But why are there such large differences in their interchangeability ratios? The answer lies in the different criteria established by each manufacturer as valid for deciding that two products are alternatives or interchangeable. If we analyse the most typical differences shown by interchangeable products, they are:

-

They have different technologies

-

They have different (normally superior) technical specifications

-

They have distinct qualities

-

They have distinct brands

-

They have similar components

-

They have been superseded

-

They are considered equivalents

So we can already see that numerous criteria can be used to decide if a product is considered an alternative or not.

But what would happen if we could take advantage of the majority criteria of the aftermarket (represented by 15-20 distributors and manufacturers) to decide if any two given products are interchangeable? Couldn’t we take advantage of all this knowledge to apply it in the interest of our own product range? Well, ladies and gentlemen, this is exactly what we do at Factory Data with our “product solution” technology.

With the “product solution” technology we can decide in one second about the product we’re being asked for (using any reference on the market), whether we have an alternative in our product range or in any of our preferred brands, following, of course, the majority criteria of the market.

Thanks to this technology, any wholesaler, distributor or manufacturer can increment their level of service in an extraordinary way and therefore become more efficient and sell more.

By Joan Cabós

CEO & founder